News

Biobased Lubricant for Green Machining What is a bio based product? Bio based products are derived from plants and other renewable agricultural, marine, and forestry materials. These products provide an alternative to conventional petroleum derived products and include a diverse range of offerings such as lubricants, detergents, inks, fertilizers, and bio plastics. For the purposes of … Read more

Read MoreHere we show how we can simply modify an existing band saw that had been traditionally using flood coolant and transform it into a MQL (Minimal Quantity Lubrication) application. This modification is inexpensive to implement and can be fitted up quite easily, the transformation is remarkable, watch the short video to see how we do it. There are many … Read more

Read MoreFluid mixing technology This Uni-Blend™ System is designed to accurately mix water with concentrated fluids in any ratio from 1:1 to 50:1 and deliver the mixture under pressure to a customer-supplied piping network. The Uni-Blend™ System automatically mixes batches and maintains a reserve supply of up to 50 gallons per ratio. Up to three batches … Read more

Read MoreOn the 10th year anniversary of Unist Australia, we are excited to announce the appointment of Lloyd Barker who joins the Unist team as “Applications Engineer”. Lloyd is a licensed electrician and mechanical fitter with experience working in Australia, New Zealand and the UK. Prior to joining Unist Australia, Lloyd worked in the robotic automation … Read more

Read MoreBe at the edge of metal cutting technology Take a look at this great article by our own Tim Walker. Tim discusses the pros and cons of metal cutting technology by applying Minimum Quantity Lubrication (MQL). This article originally appeared in TLT (Tribology & Lubrication Technology) Magazine’s Oct. 2016 issue. Click to read the article! … Read more

Read MoreWe are pleased to announce that Unist Coolube Advanced Metal Working Lubricants can now be bought ON LINE via our own shop located on our website. Now you can get all the benefits of Unist Coolube products without the hassle of making phone calls etc. simply follow the prompts and your order can be dispatched … Read more

Read MoreWatch us cut Stainless Steel, Chrome Steel and Cast Iron with this converted Everising saw that used to run on flood coolant.

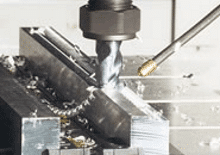

Read MoreThe Revolution™ uses our patent-pending MQL technology to integrate seamlessly with CNC machines. The system can be configured with one or two oil/air outputs which can be used for either external spray nozzles or through-the-spindle lubrication. The output volume of the Revolution™ can be tailored to each tool in a machine directly from the CNC … Read more

Read More- « Previous

- 1

- 2

- 3

- 4

- Next »