Articles.

Be at the edge of metal cutting technology Take a look at this great article by our own Tim Walker. Tim discusses the pros and cons of metal cutting technology by applying Minimum Quantity Lubrication (MQL). This article originally appeared in TLT (Tribology & Lubrication Technology) Magazine’s Oct. 2016 issue. Click to read the article! … Read more

Read MorePump-based systems: like Unist’s Coolubricator and Serv-O-Spray move the fluid using a small pneumatic pump. The pump allows precise control of the fluid output though adjustments of its stroke length and frequency. The positive displacement design ensures that exactly the same volume of lubricant is metered out with each stroke. It is the most precise … Read more

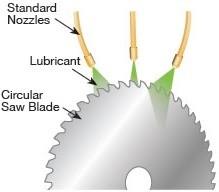

Read MoreWhen considering doing single channel MQL, whether through turret or spindle, the coolant channel passages will have an effect on how well it will work. Straight passages with no turns, cavities, or restrictions are best. Three hundred years ago, Newton observed that objects have a natural tendency to keep on doing what they are doing. … Read more

Read MoreChip removal in MQL is different than in flood cooling. In some ways it is harder; there is no fluid to wash chips away from the cut. In other ways it is better because dry chips typically move more easily and cleanly than wet ones. Fast and complete removal of chips and metal dust from … Read more

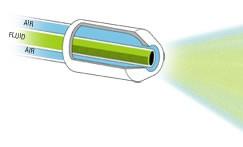

Read MoreAlthough commonly called a mist system, machining with minimum quantity lubrication has been shown to produce fewer emissions than flood cooling. It is, in fact, a low-emission process. Unfortunately, when starting with MQL, many shops think that more is better so they blast as much air as possible through the MQL nozzles and literally create … Read more

Read MoreWhen a substance reacts with oxygen, it turns into another compound altogether with a different molecular structure. This process is known as oxidation or oxidization and is widely known to occur in metals but can occur in fluids as well. Vegetable-based metal cutting fluids are affected greatly by oxidation. The effect experienced is an increase … Read more

Read MoreMetal working fluids enhance the lifespan of different metals used in the metal working process. In addition, these fluids have a superior maintenance quotient that improves performance. The commonly used products under this category are coolants and lubricants. Whereas various manufacturing units use lubricants to prevent wear and tear, coolants are widely used in the … Read more

Read MoreMetal cutting fluids are simply oil or water based fluids that are used when cutting metals. They are mainly used in the manufacturing industry to produce a wide array of items like wire, coins and other complex products. Why they are used When cutting a metal, these fluids help to cool the cutting surface, reduce … Read more

Read MoreIf your company would like to increase the factory throughput, reduce tool maintenance costs and improve product quality in a safe environment, then you may want to start using bio-based metal cutting fluids. These fluids have superior viscosity and excellent lubricity. To achieve the goal of energy independence and a cleaner surrounding, then you may … Read more

Read MoreThe usage and environment of metal cutting fluids cause them to change over time. So, a similar product can have a very different composition after using it in certain systems for sometime. Therefore, fluid maintenance is crucial for a better application of the fluid. Besides, keeping the properties of a fluid within the required limits … Read more

Read More