Machining & Metal Cutting Lubrication

Product Info

Machining & Metal Cutting Lubrication

At Unist, our mission is to help improve manufacturing operations. For machining and metal cutting operations, we believe there is a better alternative to flood coolant for cooling and lubricating the machining process. That better way is Minimum Quantity Lubrication or "MQL." MQL replaces the gallons of coolant machinists typically use with only a few ounces of naturally renewable lubricant. MQL not only reduces fluid use and saves money, but improves tool life, promotes cleaner shops, eliminates the need for fluid circulation, treatment and disposal, and more - all while utilizing an environmentally friendly product that's safe for your workers.

What is MQL?

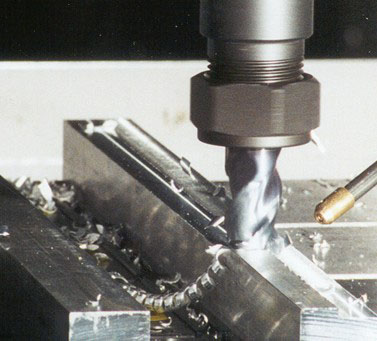

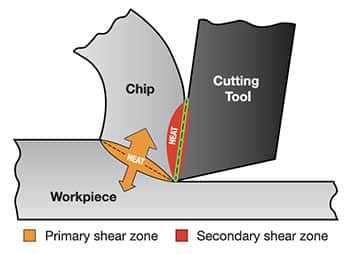

Metal cutting processes generate heat in two ways. First, the shearing action of the material causes heat buildup as the material deforms and eventually flies away as a chip. Second, the sliding friction between the workpiece and the cutting tool generates heat as the tool plunges into the material. Flood coolant typically is used to quench the heat. MQL works to reduce the heat.

By applying minute amounts of high-quality lubricant directly to the cutting tool/work piece interface, MQL works to reduce the amount of friction and therefore lowers the amount of heat generated in the process. Heat generated by material deformation flows away as the chips break off from the cut. In most configurations, lubricant is carried in an air atomized form to the cutting zone.

Benefits of Minimum Quantity Lubrication

Business

- Lower manufacturing costs

- Lower fluid costs

- Reduced cleaning costs

- Increased tool life

- Increased part quality

- Better scrap value

Employees

- Safe, non-toxic fluids

- Less safetey hazards

Environment

- 100% biodegradable fluid

- Less energy consumed in process

- Use ounces of fluid vs. gallons

Features, Specs & Options

MQL Applicator Parts

Main Parts

The main system is comprised of the reservoir, pumps, and valves that are used to dispense lubricant and air to its point of use. It may also include a protective enclosure. Reservoirs are available in several sizes to match your application’s needs and pumps can be selected to deliver the correct amount of output for the type of fluid being used. The main system can be configured with one or multiple pumps to provide fluid for one or multiple points of use. Unist MQL applicators feature a lifetime warranty on their positive-displacement pumps when Unist Coolube® lubricant is used exclusively.

Outputs

Tubing

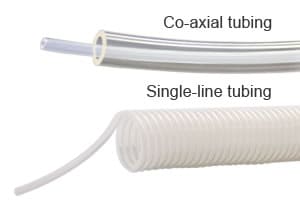

From the main system, the air and oil travel through tubing to the MQL Nozzle where they are delivered to the point of application in the form of an atomized spray. Tubing can be either dual-channel, also known as co-axial (air and oil remain separated from the main system to the point of application) or single-line (air and oil are mixed from the main system to the point of application). Each method has its strengths and Unist can help you determine which is best for you.

MQL Nozzles

Whether your application involves a drill, saw, or turning tool, Unist has a nozzle designed for your process. Sometimes existing machine routing can be used as is the case in through-turret or through-spindle MQL on lathes and mills.

Control Actuation

Unist puts the control of your MQL applicator in your hands with a variety of actuation options. Unist can build a system to your specs, from simple, manual on/off control with manual rate adjustment, to air pilot valve control, to solenoid control for varied voltages. We also build systems featuring fully automated and integrated digital control. Get in touch and a Unist will help determine the right control actuation for your needs.

Want to learn more? Contact us to talk about your process.

Related Videos

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

MQL Minute #6

Learn how to best position your nozzles for milling operations in this MQL Minute.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.