Coolubricator JR™

Product Info

Compact performance

- Continuous precision output

- Reliable Unist pump

- Separate air/fluid control

- Economical MQL solution

Provides small shop economy. See how this portable lubricator can lead to big lubricant savings and better quality products. Contact us today.

Coolubricator JR™ Oil Mist Lubrication applications:

- Drill presses

- Lathes

- Saws

- Open milling machines

- Boring mills

- Works with metals, woods and plastics

Coolubricator JR™ lets you lubricate machines throughout your shop

This portable lubricator moves from machine to machine without production delays. Hand-carry this versatile lubricator from one scheduled cutting or machining equipment to the next. A heavy-duty magnet lets you install it with minimal downtime.

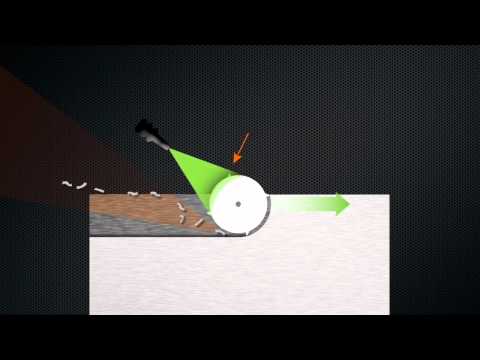

This system produces a continuous output of precisely metered lubricants. Air-driven, positive-displacement pumps precisely meter each drop of lubricant at .03 cc/stroke. The 100-million cycle pulse generator allows for automatic, infinite repeat cycling of the metering pump. This ensures that a continuous, external film of lubricant is applied to the tool-work interface.

Lets operator easily control atomization of the spray by adjusting air, pulse per minute and liquid metering.

Adjusts output from 4-200 injection cycles per minute with 0.1 to 3.0 drops of lubricant per cycle. A durable, vented 16 oz. reservoir on the CNC mister holds more than 14,400 drops of lubricant.

Dispenses any highly refined lubricant including Unist’s high-efficiency Coolube{rr} from the oil mist lubrication system's durable, 16 oz. (0.5 L) vented reservoir.

The Coolubricator JR™ combines lubricant and air in a co-axial nozzle tip. The oil mist lubrication system keeps atomization and distribution of the liquid consistent regardless of the hose length. Plastic 12 in. nozzle is coupled with 5 ft. Co-Axial hose. A heavy-duty magnetic base at the hose/nozzle connection of the oil mist lubrication system makes it easier to relocate and position the nozzle at the friction points.

Features, Specs & Options

Features

- Continuous precision output

- Reliable Unist pump

- Separate air/fluid control

- Economical MQL solution

Technical Specifications

|

|

|

|

|

|

| Outputs: |

|

|

|

|

| Nozzle: |

|

|

|

|

| Pump: |

|

|

|

|

| Reservoir: |

|

|

|

|

| Mounting: |

|

|

|

|

| Actuation: |

|

|

|

|

Options & Accessories

Accessoires

Spray nozzle options

Multiple styles/lengths available

Related Videos

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

MQL Minute #6

Learn how to best position your nozzles for milling operations in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.