Coolubricator™

Product Info

The perfect MQL metal cutting companion.

- Continuous precision output

- Reliable Unist pump

- Separate air/fluid control

- Ideal MQL solution - reduce fluid use & save!

Coolubricator™

constant signal = constant lubrication

- Reduces fluid usage

- Promotes a clean and safe work environment

- Prolongs tool life

- Improves cut quality

- Made for environmentally friendly Coolube®

- Dry chips - higher recycling value

Benefits of Using a Precision Lubricator

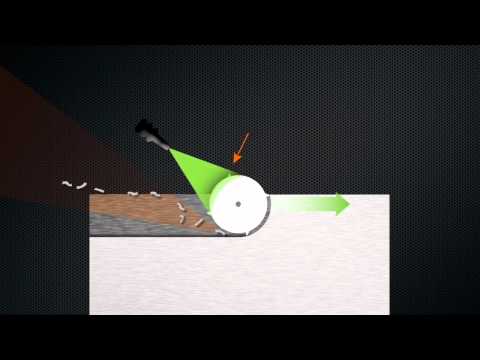

With its precision positive displacement pump and individually adjustable air and fluid volumes, the Coolubricator™ precision lubricant system is the perfect Minimum Quantity Lubrication solution for metal cutting.

Roll over image for component info

Dial in the "Sweet Spot"

With MQL, individual metal cutting applications each have their own "sweet spot" or precise amount of fluid necessary for optimum efficiency. Too little fluid, or too much fluid and tool life can suffer and fluid can be wasted. The Coolubricator™ gives you precise control over fluid output with separate fluid and air output adjustment. This means finding the sweet spot for your application is a breeze and once it's set, you can count on the Coolubricator™ to deliver the perfect amount of fluid again and again.

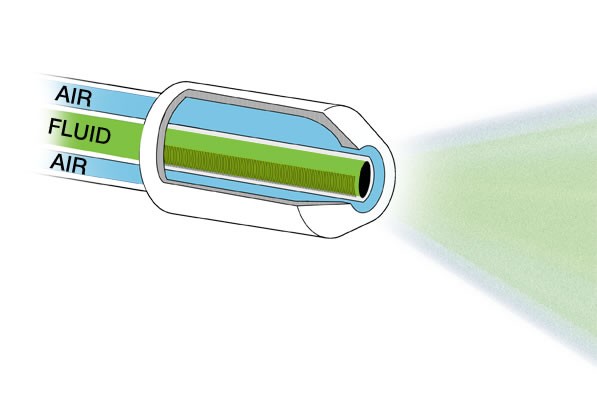

Separate Air & Fluid

is the key to delivering consistent atomization and fluid distribution over extended lengths of supply tubing. This is where the patented Unist Co-Axial Nozzle steps in. Fluid and air are kept separate until they are combined at the nozzle tip. This creates an evenly atomized spray and eliminates messy drips. Be sure to order your Coolubricator{tm} with Co-Axial hose and nozzle to maximize your lubricant delivery!

Features, Specs & Options

Features

- Produce dry chips with higher recycling value

- Eliminate flood coolant treatment & disposal

- Apply ounces per day instead of gallons

- Eliminate carbide tool thermal shock

- Eliminate flood coolant mess

- Increase production rates

- Improve surface finish

- Extend tool life

Technical Specifications

|

|

|

|

|

|

| Outputs: |

|

|

|

|

| Pumps(4 types available): |

|

|

|

|

| Actuation: |

|

|

|

|

| Reservoirs: |

|

|

|

|

Options & Accessories

Mounting

Magnet mounts

Mount securely to magnetic surfaces. Includes 4 strong, rare-earth magnets each capable of supporting 15lbs of weight for a total of 60 lbs, and mounting hardware.

Bolt-on

Mount securely using 5/16" (7mm) dia. mounting flange holes and your own compatible hardware (no hardware supplied).

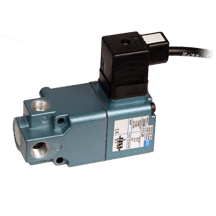

Actuation

Air pilot valve

For use with a low-flow air signal.

Solenoid valve

For actuation using an electrical signal from the machine.

Manual valve

3-way slide valve for simple manual on/off control.

Foot valve

Hands-free manual operation.

Pump

Standard 1-drop pump

(0.03 mL per stroke)

Standard 3-drop pump

(0.10 mL per stroke)

Multi-Viscosity 1-drop pump

(0.045 mL per stroke) Select this option to match your fluid delivery needs

Multi-Viscosity 2-drop pump

(0.10 mL per stroke) Select this option to match your fluid delivery needs

Multiple outputs

1-3 outlet enclosure

4-6 outlet enclosure

7-11 outlet enclosure

12-16 outlet enclosure

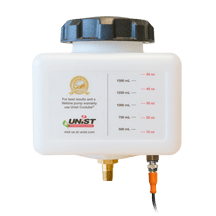

Reservoirs

16 oz [473 mL] polyethylene

32 oz [946 mL] polyethylene

64 oz [1893 mL] polyethylene with low level switch

(Also available without a low level switch)

Air trap

For use with a pressurized fluid supply.

Accessories

Spray nozzle options

Multiple styles/lengths available

Related Videos

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

MQL Minute #6

Learn how to best position your nozzles for milling operations in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.