Saw Blade Lube System™

Product Info

Cutting edge technology

- Eliminate the mess of flood coolant

- Reduce fluid usage

- Extend blade life

- Dry chips are worth more money

Saw blade lubrication improves blade life & eliminates messy coolant!

Unist Saw Blade Lube Systems™ and Band Saw Lubrication Equipment deliver all the benefits of MQL (Minimum Quantity Lubrication) to your band or circular saw in a durable and easy to install package. Longer lasting blades, better cuts, fluid savings, and clean, dry chips are the main reasons users love our Saw Blade Lube Systems™ and our Coolube® lubricant.

If you’re currently using a traditional flood coolant system, make the switch to a Unist Saw Blade Lube System™ and eliminate the mess that coolants can cause, their health/safety concerns, and the need to treat and dispose of them.

Unist offers numerous system options to make sure your Saw Blade Lubrication System™ is perfect for your application whether circular sawing or otherwise, and we’ll work with you to make sure your system is a success. Get started enjoying the benefits of saw blade lubrication and MQL today!

Improved results: sawing Inconel with Unist

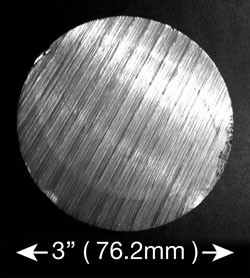

The images at right are courtesy of a Unist customer sawing 3" Inconel bar stock with band saw lubricant. The cut was made with a Lenox 19'2 x 1.5"H bi-metal blade on a Hydmech HYD-M.

Before:

The photo on the left shows cut quality before the Unist system was added. This cut was made using typical flood coolant and resulted in a blade life of approximately 5 days. As you can see, the cut has generated excessive chatter and a large burr on the edge of the stock (click each image for a larger view).

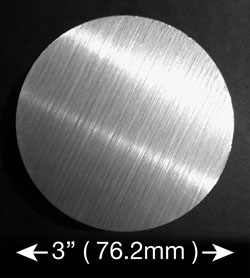

After:

The photo on the right shows the same material cut with the same blade after a Unist band saw lubrication system was installed. The cut was made using our Coolube® 2210EP lubricant. Not only was the cut quality greatly improved, but the customer experienced a substantial blade life increase! This customer was able to eliminate the cost and mess associated with flood coolant and also saves considerably on blade costs.

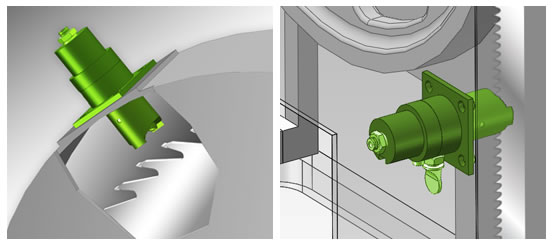

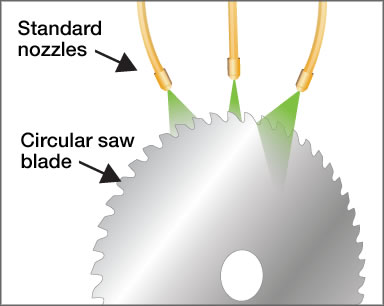

Bat Nozzle – Our Standard Nozzle For Circular And Band Saws

The Bat Nozzle was designed to easily fit on a wide variety of circular saws, vertical band saws, and horizontal band saws. The nozzle includes a 1.75” (45 mm) square mounting flange that can be attached to the blade guard. A 1” (25 mm) diameter hole drilled through the guard allows the nozzle to be centered over the blade. The nozzle position can then be adjusted as close to the blade as required with a thumb screw. Two outlets on the sides of the blade and a third outlet spraying directly into the gullet of the teeth assure superior application of lubricant to the saw blade. The Bat Nozzle is available in various lengths to accommodate a broad range of saws.

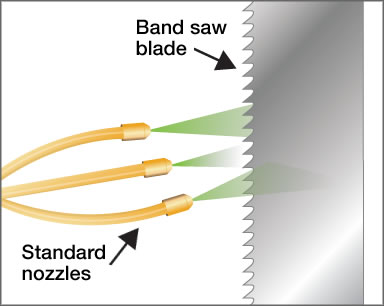

On some horizontal band saws, there is not enough room to mount the Bat Nozzle. For these situations, Unist offers two additional nozzles engineered specifically for horizontal band saw lubrication applications.

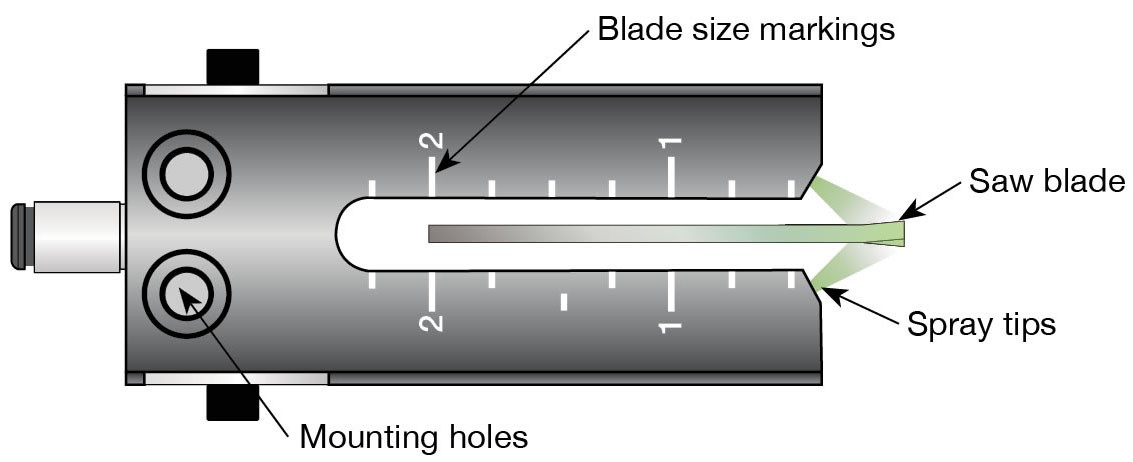

Band Saw Blade Nozzle

The Band Saw Blade (BSB) Nozzle provides users with alternative mounting options and delivers an ideal spray pattern for horizontal band saw blade lubrication. Its smaller footprint makes for easier mounting and less intrusive installation.

When mounted to the blade guide, proper positioning is easy when using the built-in ruler guide. Simply align the top of the blade with the appropriate blade size marking and secure the nozzle in place. For additional mounting flexibility, optional brackets are available. The BSB Nozzle is available in sizes for 1” [25.4 mm], 2” [50.8 mm], and 3” [76.2 mm] sizes to accommodate most common band saw blade widths.

The BSB Nozzle is ideal for:

- Horizontal band saw blades up to 3" [76.2mm]

- Mounting on blade guides

- When spraying from the top of the blade is preferred

The Band Saw Guide Nozzle

The Band Saw Guide (BSG) Nozzle will lubricate the sides of the blade to help minimize friction when blade guide lubrication is required.

The BSG Nozzle can be mounted directly to a guide block or to the BSB Nozzle. When paired with a BSB Nozzle, this will provide lubrication for both the cutting edge and the sides of the blade.

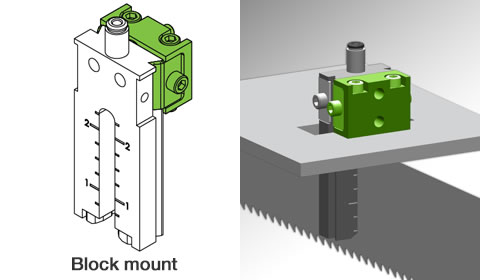

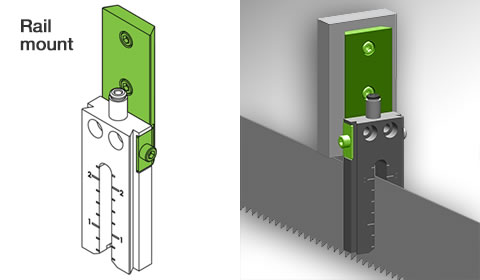

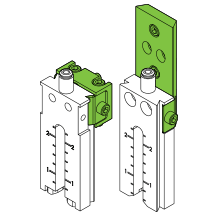

Mounting Kit

For maximum mounting flexibility, two mounting brackets are available for the band saw nozzles. The block mount allows either a blade or the guide nozzle to be held 90 degrees from the mounting surface. The rail mount allows the vertical height of the BSB or BSG Nozzles to be easily adjusted by sliding the nozzle up or down and tightening the clamp at the side.

Two mounting options are available:

Other saw blade lubrication nozzles

Unist also manufactures a wide variety of stainless steel, copper, and plastic nozzles, which offer the ability to quickly and easily install our systems on any saw where mounting the nozzles above may not be feasible.

Our nozzles are available in a variety of lengths, styles, and mounting options so they can be tailored specifically to your band saw lubrication needs.

Features, Specs & Options

Features

- Eliminate the mess of traditional flood coolant

- Save money with reduced fluid usage

- Extend blade life & reduce downtime

- Dry chips are worth more when recycled

Technical Specifications

|

|

|

|

|

|

| Outputs: |

|

|

|

|

| Pumps(4 types available): |

|

|

|

|

| Actuation: |

|

|

|

|

| Reservoirs: |

|

|

|

|

Options & Accessories

Actuation

Air pilot valve

For use with a low-flow air signal.

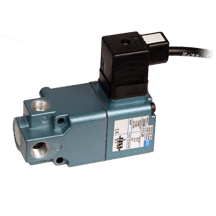

Solenoid valve

For actuation using an electrical signal from the machine.

Manual valve

3-way slide valve for simple manual on/off control.

Foot valve

Hands-free manual operation.

Pump

Standard 1-drop pump

(0.03 mL per stroke)

Standard 3-drop pump

(0.10 mL per stroke)

Multi-Viscosity 1-drop pump

(0.045 mL per stroke) Select this option to match your fluid delivery needs

Multi-Viscosity 2-drop pump

(0.10 mL per stroke) Select this option to match your fluid delivery needs

Multiple outputs

1-3 outlet enclosure

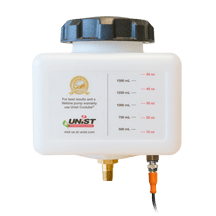

Reservoirs

16 oz [473 mL] polyethylene

32 oz [946 mL] polyethylene

64 oz [1893 mL] polyethylene with low level switch

(Also available without a low level switch)

Output type

BAT nozzle

The Bat Nozzle fits on a wide variety of circular saws, vertical band saws, and horizontal band saws.

Band Saw Blade Nozzle

The Band Saw Blade Nozzle provides alternative mounting options and delivers ideal spray pattern for horizontal band saws

Band Saw Guide Nozzle

The Band Saw Guide Nozzle lubricates the sides of the blade to minimize friction when blade guide lubrication is required.

Mounting

Band Saw Nozzle Mounting Kit

For maximum flexibility, every Band Saw Nozzle Mounting Kit includes two mounting brackets. The block mount allows either a blade or the guide nozzle to be held 90 degrees from the mounting surface. The rail mount allows the vertical height of the BSB or BSG Nozzles to be easily adjusted by sliding the nozzle up or down and tightening the clamp at the side.

Related Videos

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #5

Learn about Unist's specialty BAT nozzle for sawing in this MQL Minute.

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing a Uni-Max Pump Rebuild Kit

In this how-to video, the installation procedure for a standard Uni-Max Pump rebuild kit is outlined.