News

Watch how we drill 25 mm diameter holes through toughened steel tube with a wall thickness of 5 mm, the hole is drilled through both walls. To use traditional coolant would have made an absolute intolerable mess, with coolant running down the tube creating a safety hazard and customer quality issues. The manufacturer here decided … Read more

Unist only uses the finest material in our pumps: Stainless Steel, Brass, Aircraft grade aluminium and Viton for the seals, which makes the pumps able to withstand the most arduous environments. Further to this, Unist machines to the closest tolerances for all the components that make up our pumps – this this how we can … Read more

Cleaning residual Coolube from parts In most cases there should be little if any Coolube left on the part. If the part has much oil on it, it may be an indication which means the MQL spray needs adjusting. But in the cases where over spray is unavoidable, or there can be no oil on … Read more

A Clean, Safe and cost effective solution to toxic waste coolant. Coolube® has distinct advantages over traditional flood coolant. This video discusses the benefits of dry chips using Coolube®

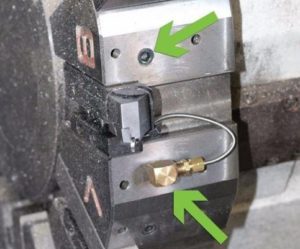

Adjust the fluid and air at the remote adjustment solenoid valve bank connected to our SPR-2000™ programmable fluid controller. Low Volume Spray Nozzles with remote adjustment and the SPR-2000™ controller control the application of metal forming lubricants and keep all controls in a central location. More information

Article written by Production Machining’s Senior Editor, Chris Felix Machining generates heat, and flood coolant is the common method to alleviate this heat. But flood coolant is a brute force solution that raises a host of issues of its own. Large quantities of coolant require specialized equipment to circulate, filter and test, and the purchase, … Read more

In this MQL Minute, John and Larry discuss the benefits of Coolube® vs. traditional flood coolant.

The customer had been machining this Nickle Alloy dry (No Coolant) because to add coolant to the process would have meant mess everywhere, a cost the customer wasn’t prepared to tolerate.

Development of very thin carbide tip and cermet tipped saw blades have attracted industries to use them for mass metal sawing applications as material cutting wastage or kerf loss is very similar to that of band saw machines. With the technological development of the blade, micro mist spray oil and high accuracy gear boxes, the … Read more

- « Previous

- 1

- 2

- 3

- 4

- Next »