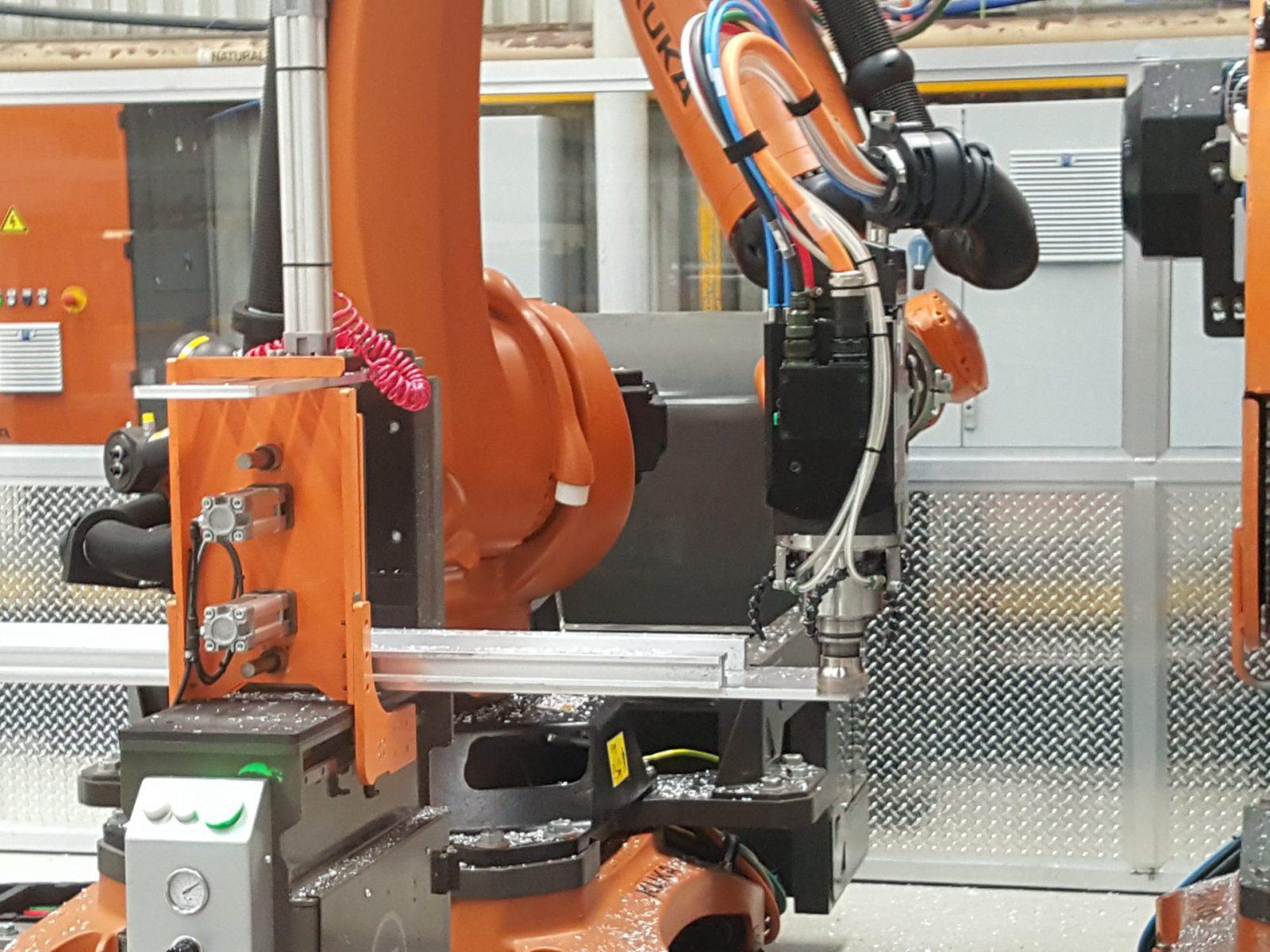

This brand new saw installation never saw one drop of Coolant. The customer insisted that this new machine had to be fitted with an oil spray lubrication system to lubricate the band saw blade. The benefits of this cost effective alternative are many, here are just a few:

This MEP machine is capable of cutting right and left miters up to 60 degree… the customer gets a finished product free of cutting contaminations. For the saw owner he has an easy/clean job cleaning up using a dry industrial vacuum cleaner.

In short, the benefits of Unist Coolube® with MQL are:

- Significantly increases blade and tool life.

- A cost effective conversion for all machine types.

- No waste – kind to the environment and no wasting money either More economical in the long run – using Coolube® preserves machine parts for longer and prevents rusting

- Clean – no more messy slip hazards from excess coolant oozing down machines and walk ways

- The MQL system dispenses precisely the amount of Coolube® needed. No more, and no less.

- Better for machine operators – no more dermatitis caused by skin contact with coolants.

- Coolube does not oxidise or go sticky.

Nowadays, many manufacturers are under pressure to “go green”. Unist Coolube® is one of the most advanced metalworking fluids available today. Implementing Minimum Quantity Lubrication (M.Q.L.), a no-waste dispensing system, with Unist Coolube® is an easy step to limit the environmental footprint of your manufacturing operation.

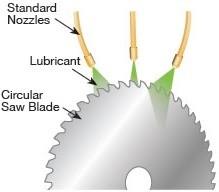

MQL is the process of applying minute amounts of high-quality metalworking fluid lubricant directly to the cutting tool or work piece interface instead of using traditional flood coolants. It minimises your environmental impact by significantly reducing fluid usage and eliminating the need for coolant treatment and disposal.

These benefits are multiplied further when using 100% biodegradable Coolube® lubricants, *that is*, metalworking fluids which are formulated from renewable plant-based oils. When considering these facts, along with the performance benefits of Coolube® and MQL, it becomes obvious that this is the most advanced and responsible answer to running metal cutting and metal forming equipment.

Using the right lubricant is very important in MQL applications. The perfect lubricant will adhere to the surface of the tool and provide a thin, low friction barrier between the cutting tool and work piece. Studies have shown that Coolube® has superior properties, which make it an ideal lubricant.

Coolube’s® polar properties create a strong consistent bond between Coolube® and metallic surfaces. This creates an even, strong, and durable layer of lubrication. Coolube® reduces friction 50% better than typical mineral oils preventing heat build-up and resulting in longer tool life and a superior cut finish.

At Unist, we’ve been manufacturing green products long before the hype. Since 1957 to be exact.

With our recent USDA BioPreferred Program certification, everyone can see just how green our lubricant products are. These are the same non-toxic, environmentally friendly, green products we’ve been touting for years.

Nothing has changed but the USDA’s certification of our bio-based content through independent laboratory testing.

Unist Coolube® 2210 and 2210EP are both USDA BioPreferred products and are tested and certified biobased products. Coolube® 2210 is certified biobased with a renewable, biobased content of 93%. Coolube® 2210EP is a certified lubricant with a biobased content of 92%.This reinforces what we’ve know about Coolube all along:

it’s made from natural and renewable plant-based materials.

They’re still the same great lubricants that thousands of metalworkers have come to love and rely on

for improved cut quality and tool life. They just have new USDA feathers in their caps!