Articles.

While any metal cutting fluid is good for work pieces, it may pose serious health concerns to your body. This happens when you come into contact, inhale or ingest the fluid. The risk depends on various factors such as personal hygiene and equipment maintenance. The severity of the health concern caused by the fluids depends … Read more

Have you fully comprehended metal cutting? Well, this is a complex subject that involves various processes and tools. There are two main metal cutting processes that are very crucial. The first term is metal cutting fluids, while the second term is known as metal cutting technologies. With these two terms, you are well able to … Read more

Are we safe in using metal working fluids and cutting fluids? This is a concern for a majority of people who normally engage in processing metals. One of the major concerns for the majority of people has been the safety in use of either the metal working fluids or the cutting fluids. What are metal … Read more

Have you come across the term metal working fluids? Well, here are several key things that will help you understand the term fully. The term is used to describe oils and liquids essential in lubricating and cooling metals during their processing. Furthermore, metal cutting fluids will be used to reduce heat and prevent premature tool … Read more

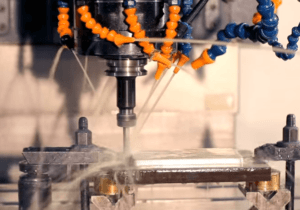

There are several products available in the markets that are vital for cutting metals. These include metal cutting fluids and cutting oils. The products are developed to meet various needs in processing of metal and their cutting. Firstly, reducing heat and friction in metal processing and cutting is very essential. Metal cutting fluids are essentially … Read more

Metal cutting and processing is a complicated activity that involves use of various techniques. The process involves use of a variety of materials. Some of the tools in consideration include metal cutting fluids and cutting oils. The choice of using either of these will majorly depend on the complexity of the task and the costs … Read more

Metal cutting fluids are specially formulated fluids for metal processing and have various distinct functions. These functions include: helping to ensure that a tool has longer life, minimizing thermal deformation, bringing a finer finish on the working surfaces and eliminating chips from the metal surfaces one is working on. Metal cutting fluids are further categorized … Read more

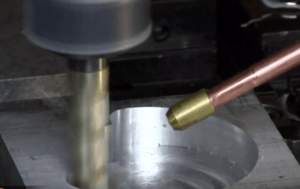

Coolube 2210 & 2210EP are high performance vegetable-derived oils developed specifically for MQL metal cutting operations. The use of minute applications of Coolube vegetable oil-based lubricants in machining operations reduces heat generation and improves speed production, surface finish, tool life and reduce housekeeping while eliminating the collecting, treating and disposal considerations associated with flood coolants. The … Read more

Near dry machining can be described in three ways: Minimum Quantity Lubrication (MQL) Micro-Fluidisation. (MF) Near Dry Machining. (NDM) They all mean the same thing and this technology is now available through Unist Australia P/L. Near Dry Machining (NDM) techniques can be applied to almost any metal cutting or metal working application where you are … Read more

Vegetable lubricants may be refined from every seed and “nut” known to man. Every seed has its own particular set of chemicals and properties. Unist Coolube products 2210 and 2210EP are formulated from cosmetic grade raw materials, the end product is non-flammable, non-toxic and does not oxidise ( evaporate) like many other cutting oils. Metal … Read more

- « Previous

- 1

- 2

- 3

- 4

- Next »