News

- All

- Articles.

- Band Sawing

- Circular Saws

- Metal Cutting

- Metal Forming

- News

- Roll Forming

- Sawing Applications

The essential processes in metal cutting

Have you fully comprehended metal cutting? Well, this is a complex subject that involves various…

Safety concerns with using metal working fluids and cutting fluids

Are we safe in using metal working fluids and cutting fluids? This is a concern…

All you need to know about metal cutting oils

Have you come across the term metal working fluids? Well, here are several key things…

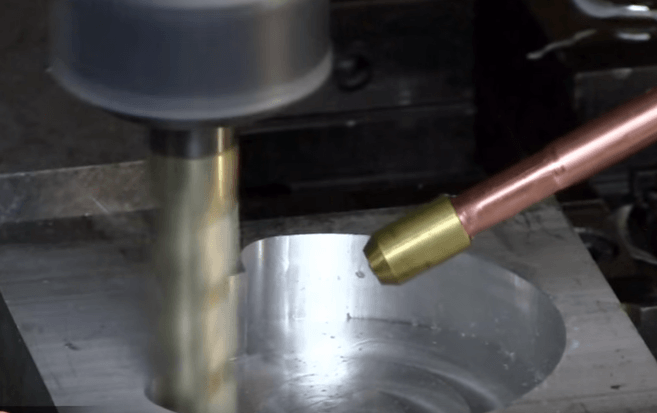

Understanding metal cutting fluids

There are several products available in the markets that are vital for cutting metals. These…

Types and uses of metal cutting fluids

Metal cutting and processing is a complicated activity that involves use of various techniques. The…

A sneak preview of metal cutting

Metal cutting fluids are specially formulated fluids for metal processing and have various distinct functions….

How to lubricate your mandrel bending and have no oil spillage issues

A dry, clean, OH&S compliant installation which meets world best practice for mandrel bending.This method…

How to obtain no mess roll-forming

This material 5mm thick galvanized steel, the machine is equipped with a Unist Roller system and Sproller controller.

How to Roll-form U section using an advanced metal working lubricant

This is truly a cost effective alternative that is fully controllable and gives absolute consistent results.

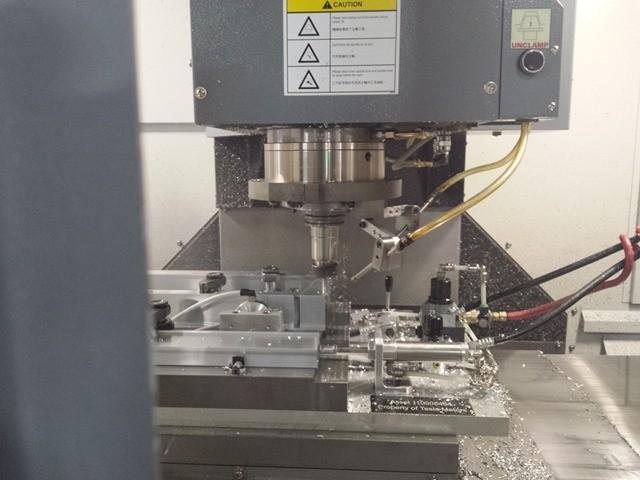

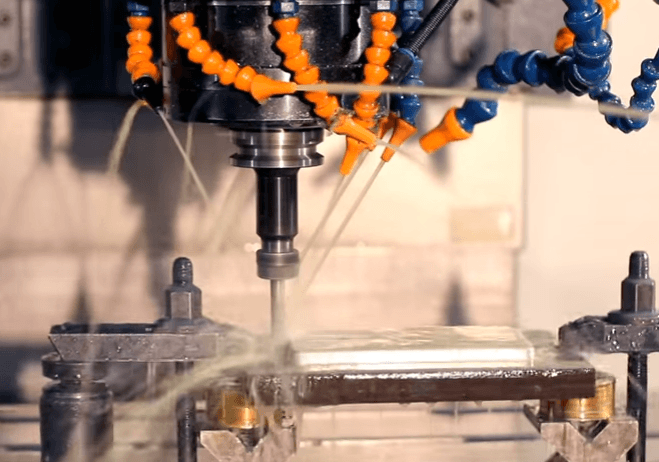

How to increase tool life by 100X

A recent study looking at micromilling 316 L stainless steel with Minimum Quantity Lubrication (MQL)…

How to ditch the coolant on your cold saw

The conversion is easy and cost effective, the system runs on Coolube 2210 vegetable oil and only uses 10ml of oil per hour.

Ditch the coolant on your band saw

Watch us cut Stainless Steel, Chrome Steel and Cast Iron with this converted Everising saw that used to run on flood coolant.