Metal Forming

A dry, clean, OH&S compliant installation which meets world best practice for mandrel bending.This method of MQL (Minimum Quantity Lubrication) uses 10ml of Coolube 2210EP per running hour. There are many benefits to be gained by employing the Unist “Near Dry Bending” mist system. In short, the benefits of Unist Coolube® with MQL are: Significantly … Read more

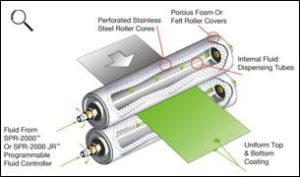

Read More about How to lubricate your mandrel bending and have no oil spillage issuesThis material 5mm thick galvanized steel, the machine is equipped with a Unist Roller system and Sproller controller.

Read More about How to obtain no mess roll-formingThis is truly a cost effective alternative that is fully controllable and gives absolute consistent results.

Read More about How to Roll-form U section using an advanced metal working lubricantThe Unist Uni-Roller was chosen for its Precise, accurate and repeatable oil delivery. Electrolux Home Products at Orange NSW had to produce a new fridge door for their latest product launch. They chose to fit a Unist Uni-Roller which would apply exact amounts of evaporating lubrication to the top of the sheet before it went … Read more

Read More about Australian white goods manufacturer chooses Unist