Articles.

It is always good to use efficient metal cutting fluids because it is not only good for you but also for the machines. A good fluid whose use is on the increase is vegetable oil and specifically, the coolube 2210. Here are its main benefits: It is inexpensive if applied the correct way This means … Read more

Recycling is the process that involves the elimination of cutting fluid disposal. Given the ongoing changes in environmental regulations across the globe, recycling is becoming an essential part of most industries. In the 1960s, many people did not care about the danger posed by used cutting fluids. Consequently, they did not perform any treatment prior … Read more

Selecting the right metal cutting fluid can take time and be an information overload. To select the fluid that is the right solution for your needs, you should review the options and benefits of each metal working fluid. Start by reading the product and supplier information and have a conversation with your local supplier or … Read more

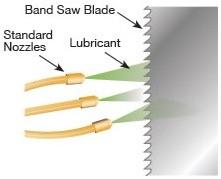

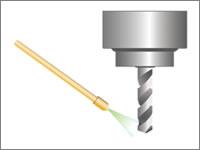

Cutting fluids are an instrumental part of metal machining due to their improvement of the tool life, reduction of the work piece thermal radiation, flushing away chips from the cutting area, and improving the surface finish. There are five main categories of cutting fluids – straight oils, synthetic oils, soluble oils and semi-synthetic and Unist … Read more

A coolant is a mineral based cutting fluid which is mixed with water. For decades, people have been using coolants to remove heat for various metal cutting operations with amazing benefits as explained below. Improving part quality Using cutting fluids reduces heat and friction. Removing the heat ensures that the work piece does not expand … Read more

A cutting fluid should have specific characteristics to be effective at cutting metal. Here are some of the major properties to look out for: Good heat transfer performance: This will reduce the amount of heat given off during cutting and therefore reduce the chances of accidental fires. It also ensures the metals will not be … Read more

Metal cutting fluid is used in metalworking and machining for different purposes, predominantly lubrication and cooling. It comes in various different forms including synthetic fluids, semisynthetic fluids, oils and soluble oils. Synthetic fluids are made of alkaline compounds and compounds that prevent corrosion. They are used in diluted water and are the premier product in … Read more

Metal working fluids are used to remove particles during grinding and machining procedures. They reduce the amount of heat and friction produced and can be referred to as metal cutting fluids. They are a powerful resource in the machine industry yet due to their complex chemical compositions, they require extra care and consideration when working … Read more

The world market is flooded with many kinds of metal working fluids. It has both trusted and suspicious brands. Working well with such fluids is easy if you follow simple guidelines. For instance, there are many companies that manufacture different classes of such fluids. Availability of cutting fluids does not imply quality or safety of … Read more

Metal working fluids (MFFs) refer to a collection of oils, together with other liquids used as coolants or lubricants when working with metal cutting processes. When milling, machining, or grinding metal work pieces, friction and heat develops between the cutting tool and the metal work piece, therefore you need certain oils and fluids in order … Read more

- « Previous

- 1

- 2

- 3

- 4

- Next »