Mini-Roller™

Product Info

Intelligent stock coating solution

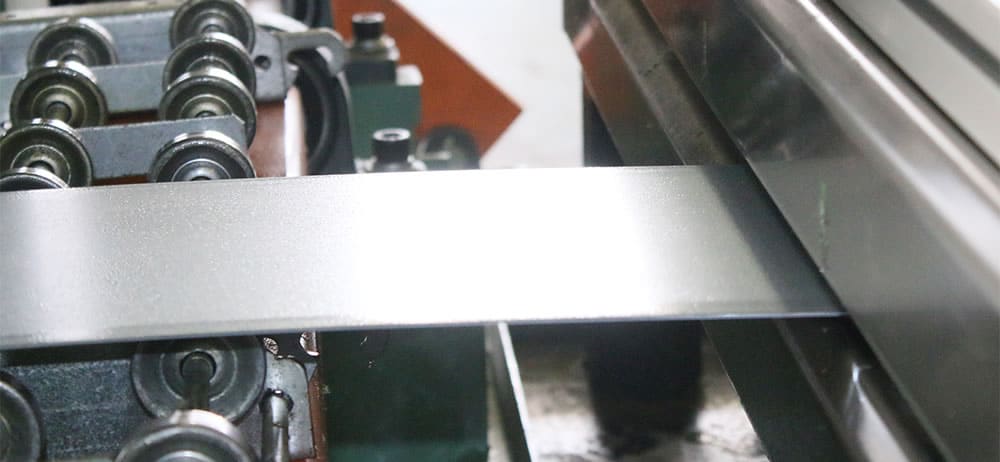

The Mini-Roller™ applies the correct amount of fluid for your small press window and high-speed, short feed length applications when combined with a SmartFlow® programmable fluid controller. This 1 to 6 in. wide (25 mm to 152.4 mm) unit consistently applies the correct amount of fluid and lets you start saving now.

- Uni-Roller® precision for narrow coil

- Internally-supplied rollers

- Consistent fluid application

- Neat application - No fluid mess!

- Horizontal or vertical

- Reduces fluid usage - Saves money!

Mini-Roller™ reduces fluid usage and saves money

On average, a Unist system can reduce stamping fluid consumption by 50% with some customers reporting reductions as high as 90%!

2 configurations

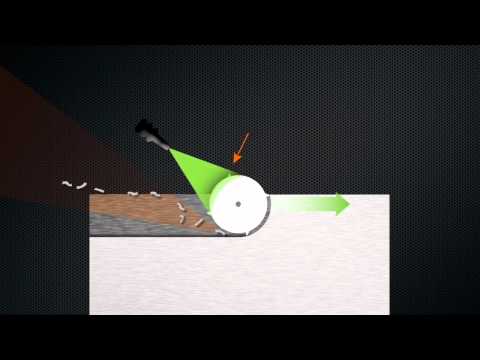

Vertical model uses a baffle positioned inside each of the rollers near the top. Every time the fluid controller injects lubricant into the dispenser tube, the fluid spreads across the baffle and is redirected to the outside of the roller. Gravity pulls fluid down the length of the cover.

Mini-Roller™ applications:

- Small press windows

- High-speed, short-feed lengths

- Thin stock

- Punching

- Stamping

- Roll forming

- Four slide

- Many other metal forming applications

Delivers return on investment in less than 6 months

That's what many of our customers report. By applying the proper amount of fluid, the Uni-Roller® lubricator uses 50 to 90% less lubricant for coil lubrication. Plus it decreases the mess, the parts cleaning, fluid recycling and costs associated with in-die spray systems, rag technology and externally lubricated rollers.

Available widths

Both vertical and horizontal Mini-Rollers™ are available in 1" (25mm), 2" (51mm), 3" (76mm), 4" (102mm), and 6" (152.4mm) widths

Available roller covers:

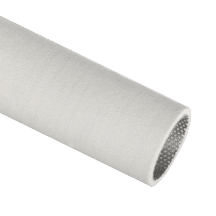

Polyester felt (standard)

Extremely durable and compatible with a broad range of fluids

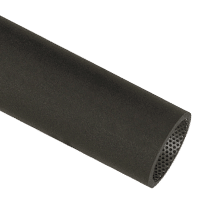

Polyurethane foam cover (optional)

For use with vanishing oils and with thin stock which is narrow compared to overall roller width. Limited fluid compatibility, please contact Unist before selecting this option.

The internally-supplied difference

The internally-supplied rollers are essential to precisely applying the fluid. Inside each of the rollers is a dispenser tube with small holes placed along its length. Fluid is injected into the dispenser tubes from the fluid controller and dispensed across the inside of the rollers.

The lubricant is transferred to the stock through durable polyester felt or polyurethane foam roller covers. These cover materials apply the lubricant smoothly and evenly across both the top and bottom of the stock.

The Uni-Roller® S2 Powered applies the exact amount of lubricant required. This eliminates the mess and waste associated with in-die spray systems and externally lubricated roller systems. The result is not only a cleaner shop, but also significant savings from decreased fluid waste, improved die life, better part quality and increased machine up-time. Many customers have reported savings resulting in a return on investment of less than six months!

Take control with the SmartFlow®

The SmartFlow® alerts you to issues before they become expensive problems that interrupt or stop your production lines. With the SmartFlow® you'll know immediately if the fluid supply runs low, if fluid pressure varies, or if flow to the applicator is interrupted (Level, pressure, and flow sensors required). The SmartFlow® features an intuitive, easy-to-use interface as well as an access code to prevent unauthorized tampering or changes in fluid settings.

- Monitors critical parameters

- Controls up to 22 outputs

- Stores up to 250 setups

Easy to use touch screen interface.

The SmartFlow® controller can monitor pressure, flow, valve performance and line status.

Job setup wizard makes job creation easy.

Features, Specs & Options

Features

- Uni-Roller® precision for narrow coil

- Internally-supplied rollers

- Consistent fluid application

- Neat application - No fluid mess!

- Horizontal or vertical

- Reduces fluid usage - Saves money!

Technical Specifications

|

|

|

|

|

|

| Stock type: |

|

|

|

|

| Stock thickness: |

|

|

|

|

| Stock width: |

|

|

|

|

| Fluid type(s): |

|

|

|

|

| Fluid supply: |

|

|

|

|

| Applicator material: |

|

|

|

|

| Controller: |

|

|

|

|

| Power: |

|

|

|

|

| Mounting: |

|

|

|

|

Options & Accessories

Roller covers

Polyurethane foam cover

Reduces uneven wear on cover when a variety of stock widths and thicknesses are used. Due to limited fluid compatibility, consult Unist.

Polyester felt cover

Extremely durable and compatible with a broad range of fluids.

Sensors

Rotation sensor

Provides an input signal to an SPR-2000™ controller based on roller rotation. Select when an intermittent signal from press not available.

Supply & Connections

In-die quick connect

Allows for permanent spray nozzle mounting to the die. Ensures nozzles remain in correct position with each die change.

Related Videos

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

MQL Minute #6

Learn how to best position your nozzles for milling operations in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.