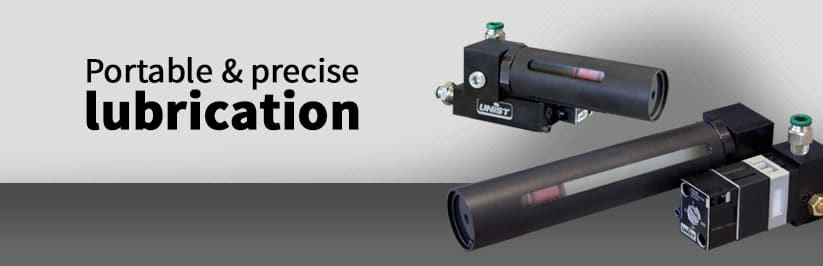

Mini-Piggyback™

Product Info

Portable cutter lubrication system

- Increases cutting tool life

- Improves hole quality

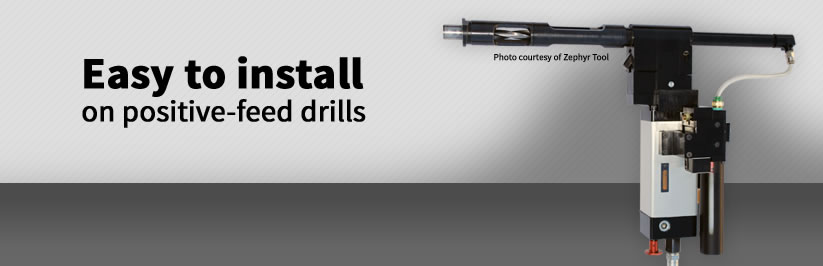

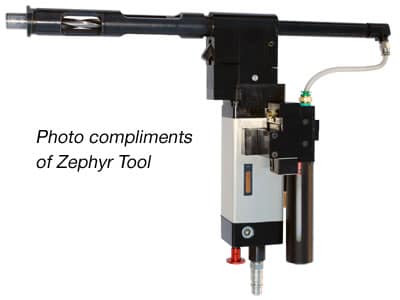

- Easy to install on most positive feed drills

- 100% Pneumatic - no electricity required

The Unist Mini-Piggyback™ system sets a new standard for lubricating cutting tools on positive feed drills. This system uses a positive displacement pump to precisely apply the right amount of lubrication to the cutting tool, hole after hole. The operator can easily adjust both the fluid and the air output to “dial-in” the perfect setting for any tool.

The Mini-Piggyback™ is 100% pneumatically operated. It is designed to use air supplied “downstream” from the tool trigger, so it operates whenever the tool is running. The fluid supply is contained in a removable reservoir that can easily be exchanged when empty. Empty reservoirs can be refilled using the Unist reservoir refill stations, so they’re ready to use again. The lubricant may also be supplied from a remote gravity-feed or pressurized reservoir. The Mini-Piggyback™ can dispense a wide range of lubricants with varying viscosities. Atomizing air can be easily adjusted or turned off completely.

The Mini-Piggyback™ is available in two configurations: continuous output, which provides a constant delivery of lubricant for operations with long cycle times, and intermittent-output, which provides a single shot of lubricant for smaller cutting tools with short cycle times.

Stay productive with Mini-Piggyback™

The manual Mini-Piggyback™ reservoir refill station is designed to allow swift and easy refilling of quick-change Mini-Piggyback™ reservoirs. The station fills Mini-Piggyback™ reservoirs and virtually eliminates trapped air which can cause inconsistent fluid output. Using it ensures properly filled reservoirs every time.

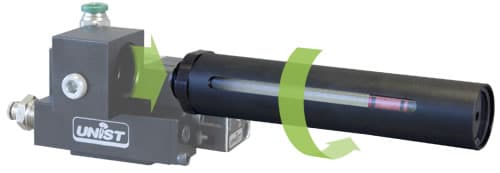

A unique feature of the Mini-Piggyback™ system is the removable, interchangeable fluid reservoir. This allows the lubricant to be replenished almost instantly by simply replacing the empty reservoir with a full one, maximizing the productivity of the tool.

Unist Coolube®

Maximize the benefits of your Mini-Piggyback™ system by filling your reservoir with Unist Coolube®.

Coolube® is a 100% natural biodegradable lubricant derived from renewable vegetable products that is friendly to the environment and machinists. It is specifically formulated to increase tool life and improve surface finishes in all machining operations. Coolube® contains no VOC’s, chlorine, or silicone. As an added bonus, Unist guarantees the pumps in our Mini-Piggyback™ systems forever when Coolube® is used exclusively.

Features, Specs & Options

Features

- Increases cutting tool life

- Improves hole quality

- Easy to install on most positive feed drills

- 100% pneumatic - no electricity required

Technical Specifications

|

|

|

|

|

|

| Injector Output: |

|

|

|

|

| Pump Rate: |

|

|

|

|

| Inlet Air: |

|

|

|

|

| Reservoir Capacity: |

|

|

|

|

Options & Accessories

Refilling

Manual Mini-Piggyback™ reservoir refill station

Allows swift and easy refilling of quick-change Mini-Piggyback™ reservoirs.

Pulse rate control

Pulse generator

with screwdriver adjustment

Pulse generator

with knob adjustment

Single shot output

Mounting bracket

for use with customer-supplied hose clamp

Mounting

Mounting bracket

for use with customer-supplied hose clamp

Related Videos

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).