SPR 2000™

Product Info

Programmable fluid controller

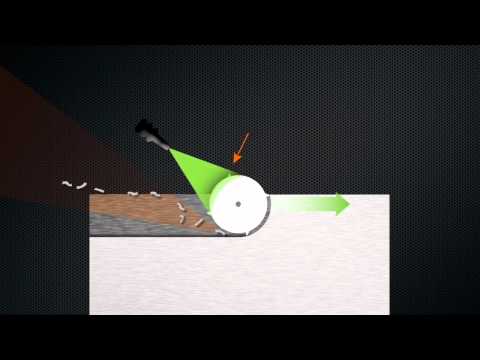

The SPR-2000™ programmable fluid controller* Controls with electronic precision and consistency how much fluid flows to one or more of these Unist systems: Uni-Roller® S2, TSL™ System, Mini-Roller™, Powered Uni-Roller® and/or Low Volume Spray Nozzles.

Patent No. 6567710*

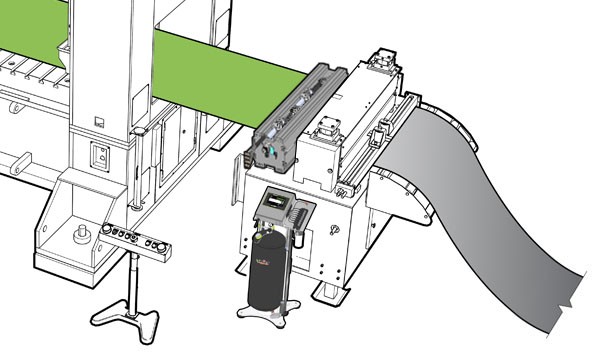

The automatic lubrication system intermittently actuates a bank of fluid Solenoid Valves (up to 22 outputs) that dispense a programmed quantity of fluid to specific lube points. The valve actuation on this electronic fluid dispenser is determined by production line rates so there is no under or over lubrication whether it is a stamping press or roll forming operation.

Benefits of Automatic Lubrication Systems

- Monitors critical parameters

- Precision fluid control

- Controls up to 22 outputs

- Stores up to 250 different setups/jobs

- Access code prevents tampering

- Saves fluid: precisely controls fluid

Combine the SPR-2000™ with a Uni-Roller® applicator to reduce fluid usage and save money

On average, a Unist automatic lubrication system can reduce stamping fluid consumption by 50% with some customers reporting reductions as high as 90%!

Full-featured monitoring

The SPR-2000™ provides full-featured monitoring of critical parameters such as fluid level, pressure and flow (optional sensors are required) and alerts users with an audible alarm and red LED. An external alarm relay can also be wired directly to a press control on this electronic fluid dispenser.

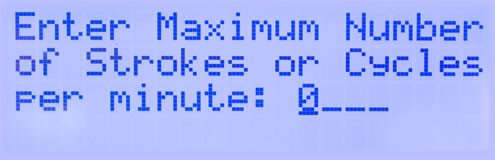

Easy set up with intuitive menus

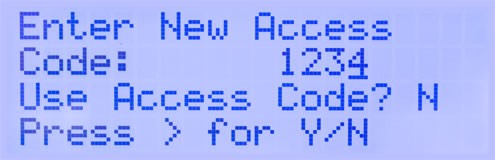

Access code menu

Provides password-protected access to the system's setting.

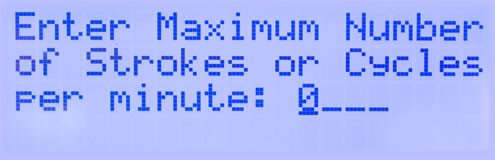

Auto setup menu

prompts the user for job specifications and automatically creates a new setup (program) for Uni-Roller® applications.

Edit menu

allows the user to modify current setups and program spray nozzles or otehr auxillary functions.

Alarm menu

allows the user to monitor critical system functions.

SPR-2000™ Applications:

Provides programmable control for the following applications/Unist systems:

- Punching (Mini-Roller™, Uni-Roller® S2)

- Stamping (Mini-Roller™, Uni-Roller® S2, Uni-Roller S2 Powered®, TSL™ System, Low Volume Spray Nozzle)

- Fine blanking (Uni-Roller® S2, Uni-Roller® S2 Powered)

- Deep Drawing (Uni-Roller® S2, Uni-Roller® S2 Powered)

- Application of rust preventives & protective coatings (Low Volume Spray Nozzle, Uni-Roller® S2)

- Fin Stamping (TSL™ System)

- Cupping / Canmaking (Coil Lubrication System™, Sheet Lubrication System™, Tab Stock Lubrication System™)

Delivers return on investment in less than 6 months

That's what many of our customers report. By applying the proper amount of fluid, the combination of an SPR-2000™ controller and Uni-Roller® lubricator uses 50 to 90% less lubricant. Plus it decreases the mess, the parts cleaning, fluid recycling and costs associated with in-die spray systems, rag technology and externally lubricated rollers.

Features, Specs & Options

Features

- User-friendly controller

- program up to 250 different die sets or jobs

- Alarm monitoring of critical parameters

- Controls up to 22 outputs

- Stores up to 250 setups/jobs

- Access code prevents tampering

- Saves fluid: precisely controls fluid

Technical Specifications

|

|

|

|

|

|

| Power supply: |

|

|

|

|

| Control inputs: |

|

|

|

|

| Alarm inputs: |

|

|

|

|

| Flow monitor inputs: |

|

|

|

|

| Outputs: |

|

|

|

|

| Valves: |

|

|

|

|

| Alarm relay: |

|

|

|

|

| Maximum input rate: |

|

|

|

|

| Minimum contact open or closed time: |

|

|

|

|

| Alarm inputs: |

|

|

|

|

| Programmable ranges: |

|

|

|

|

| Fuses: |

|

|

|

|

| Operating temperature range: |

|

|

|

|

| Storage temp. range: |

|

|

|

|

| Storage: |

|

|

|

|

| Power: |

|

|

|

|

| Mounting: |

|

|

|

|

Options & Accessories

Supply & Connections

In-die quick connect

Allows for permanent spray nozzle mounting to the die. Ensures nozzles remain in correct position with each die change.

Fluid Supply Systems

Your fluid application system needs a steady supply of pressurized fluid. Unist offers a broad range of options to meet your needs.

Related Videos

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

MQL Minute #6

Learn how to best position your nozzles for milling operations in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.