Airless Spray Nozzles

Product Info

Non-contact & supplemental applications

The Unist Uni-Roller® S2 excels at applying a continuous even coating of fluid to coil stock or a blank. However, there are times when additional fluid is needed at specific areas in the die. Unist Airless Spray Nozzles provide this extra boost. When connected to the SmartFlow®programmable fluid controller, they integrate seamlessly into the jobs lubrication profile.

- Versatile nozzle for in-die lubrication

- User-friendly design

- Requires no air to operate

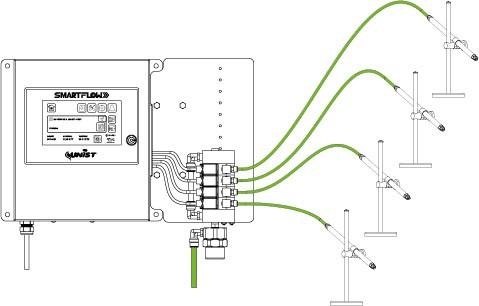

System example

The Airless Spray Nozzles connect directly to the outputs on the SmartFlow®. Up to 22 nozzles can be independently controlled or used in combination with a Uni-Roller® S2 applicator, giving maximum flexibility in coverage and control

Nozzle styles

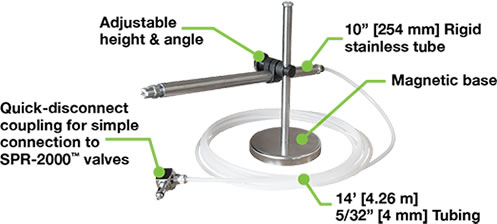

Rigid Stainless Steel Nozzle

This 10” [254 mm] Rigid Stainless Steel Nozzle includes a vertical mount that allows height and application angles to be adjusted. The Rigid Stainless Steel Nozzle offers superior rigidity, making it the preferred choice when the nozzle position doesn’t require frequent changes.

Loc-Line® Nozzle

This 12” [305 mm] flexible plastic Loc-Line® Nozzle is easy to adjust, but less rigid than the other nozzle options

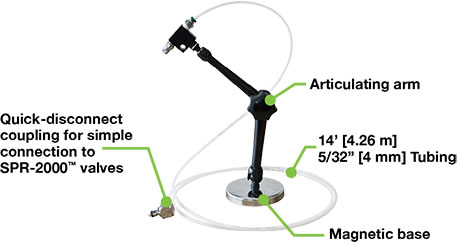

Articulating Arm Nozzle

The Articulating Arm Nozzle provides rigid positioning and can easily be adjusted and locked in place with one knob.

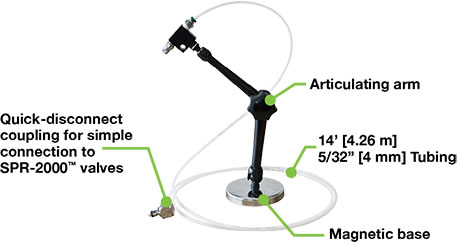

Articulating Arm Nozzle

The Articulating Arm Nozzle provides rigid positioning and can easily be adjusted and locked in place with one knob.

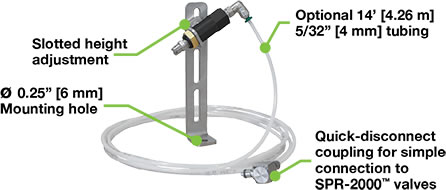

In-Die Nozzle

This nozzle rigidly attaches to the die. The slotted adjustment bracket allows for multiple nozzle positioning adjustments including nozzle height, fan spray orientation, rotation, and pivoting. Once positioned, it can be locked into position by tightening the hardware.

Features, Specs & Options

Features

- Versatile nozzle for in-die lubrication

- User-friendly design

- Requires no air to operate

Technical Specifications

|

|

|

|

|

|

| Available spray angles: |

|

|

|

|

| Available orifice size: |

|

|

|

|

Approximate spray dimensions

| B | W | ||||

|---|---|---|---|---|---|

| 0˚ | 30˚ | 50˚ | 80˚ | 110˚ | |

| 3" [76 mm] | stream | 1.6" [41 mm] | 2.8" [71mm] | 5.1" [130 mm] | 8.6" [218 mm] |

| 6" [152 mm] | stream | 3.2" [81 mm] | 5.6" [142 mm] | 10.1" [257 mm] | 17.1" [434 mm] |

| 9" [229 mm] | stream | 4.9" [124 mm] | 10.0" [254 mm] | 18.1" [460 mm] | 30.4" [772 mm] |

| 12" [305 mm] | stream | 6.4" [163 mm] | 11.2" [284 mm] | 20.2" [513 mm] | 34.3" [871 mm] |

| 15" [381 mm] | stream | 8.1" [206 mm] | 14.0" [356 mm] | 25.2" [640 mm] | 42.8" [1087 mm] |

| 18" [457 mm] | stream | 9.7" [246 mm] | 16.8" [427 mm] | 30.3" [770 mm] | 51.4" [1306 mm] |

Available flow rates

| Airless Spray Nozzle flow rate (based on water) |

|

Options & Accessories

Supply & Connections

In-die quick connect

Allows for permanent spray nozzle mounting to the die. Ensures nozzles remain in correct position with each die change.

Fluid Supply Systems

Your fluid application system needs a steady supply of pressurized fluid. Unist offers a broad range of options to meet your needs.

Related Videos

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

MQL Minute #6

Learn how to best position your nozzles for milling operations in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.