News

- All

- Aluminium Facade Routing

- Band Sawing

- CNC Machining

- Coolubricators

- Drilling

- News

- Routing

- Turning

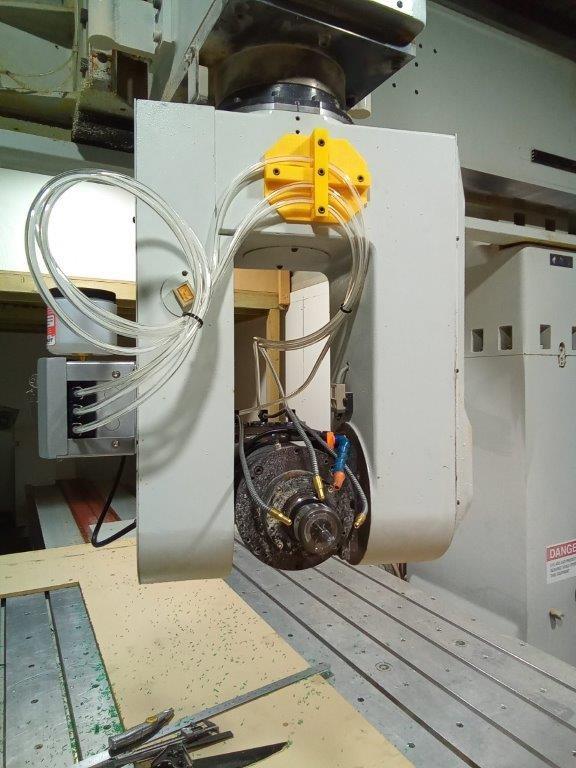

5 Axis Installation

Our customer wanted to eliminate the mess caused by flood coolant on his 5 axis…

Solution to Aluminium Facade Routing Problems

The building industry codes are changing fast and one of the more challenging changes for…

Whitepaper: Stock lubrication process monitoring and data

Your whitepaper: “How to rest easy knowing your stock is lubed – Stock lubrication process…

New 4 Gallon fluid pressure vessel

Unist has recently updated the design for small stainless steel tanks commonly used as an…

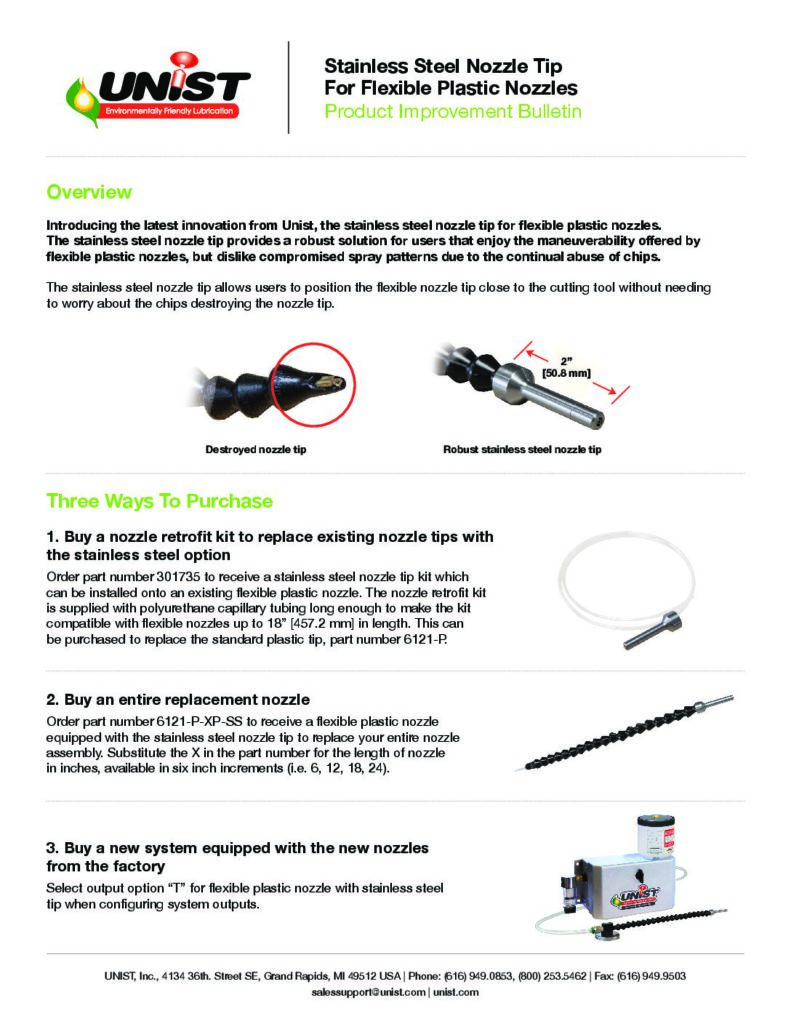

Fed up of compromised nozzle tips? It might be time for something tougher!

Plastic nozzle tips being chewed up? It might be time for something tougher!

Routing Aluminium using Methylated Spirits.

Methylated Spirits has been a very popular and widely used liquid for many companies who are…

Unist Australia: OPEN FOR BUSINESS AS USUAL

A simple message from Unist Australia to advise we are open for business. We have…

MQL in Action, Milling,Drilling, Tapping, Sawing &Turning.

Near dry Turning produces dry chips and is the way forward being discovered by many customers.

Minimum Quantity Lubrication (MQL) on CNC Lathes

This video briefly runs through MQL (Minimum Quantity Lubrication) on CNC Lathes. Implementing and enjoying…

Saw conversion from Coolant to Near Dry – no mess, dry chips

Check out our new nozzle manual. Previously running on a coolant mixture, this machine created…

Drilling 25 mm diameter holes through steel pipe.

Watch how we drill 25 mm diameter holes through toughened steel tube with a wall…

Unist’s Genuine Life Time Warranty.

Unist only uses the finest material in our pumps: Stainless Steel, Brass, Aircraft grade aluminium…