Low Volume Spray Nozzle

Product Info

Versatility & Control

Applications:

- Spraying disinfectants.

- Spraying rust inhabitants.

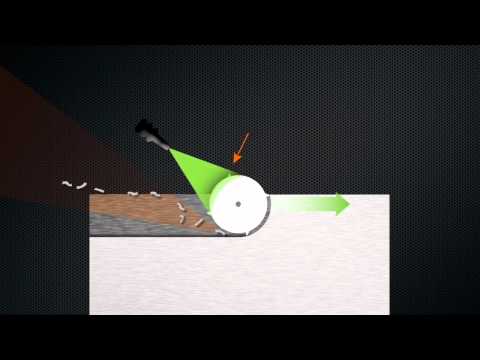

- Roll forming applications.

- Metal stamping.

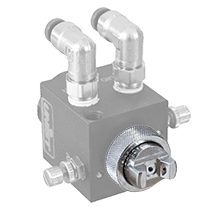

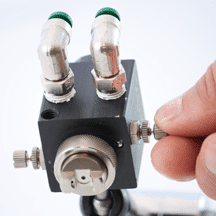

When you need precise control of your lubrication spray, the Unist Low Volume Spray Nozzle delivers with a consistent and controlled spray pattern. The air and fluid volumes are controlled independently by precision needle valves allowing you to fine tune the spray to your specific needs. An integral valve at the nozzle tip means our system features immediate on and off control which eliminates lag and prevents messy fluid drips.

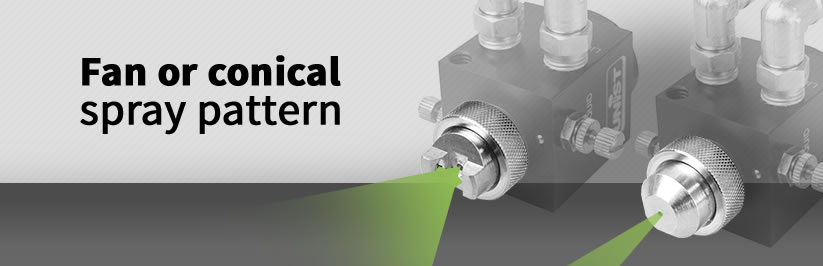

Spray Patterns

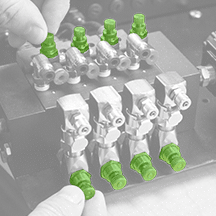

Control & Monitor Multiple Nozzles

Combine your Unist Low Volume Spray Nozzles with a Unist SPR-2000 programmable controller and pressure tank for precise control of spray frequency and duration.

The SPR-2000 is capable of controlling 22 independent Low Volume Spray Nozzles and monitoring critical parameters such as fluid level, fluid pressure, and flow and is a great choice for controlling your present and future stock lubrication systems.

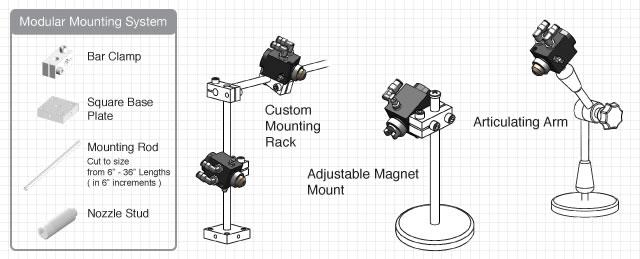

Mounting Options

Create your own mounting solution with our Modular Mounting System!

Features, Specs & Options

Features

- Valve at nozzle tip eliminates messy drips

- Immediate on/off spray control ( no lag )

- Fine control of spray pattern

- Individual air & fluid control

- Air actuated

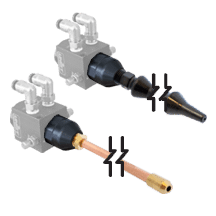

- Available with internal or external mix tip

Technical Specifications

|

|

|

|

|

|

| Fluid type: |

|

|

|

|

| Air supply pressure: |

|

|

|

|

| Fluid supply pressure: |

|

|

|

|

| Maximum cycle rate: |

|

|

|

|

| Operating temp range: |

|

|

|

|

| Body: |

|

|

|

|

| Needle valves: |

|

|

|

|

| Fittings: |

|

|

|

|

| Fluid seal material: |

|

|

|

|

| Air seal material: |

|

|

|

|

Options & Accessories

Mounting

Articulating arm

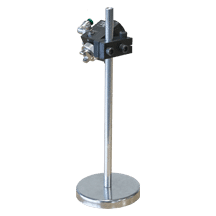

Adjustable magnet mount

Modular mounting system

Spray Tip

Fan spray tip

Conical spray tip

Extended nozzle

Adjustment

Standard adjustment

Remote adjustment

SmartFlow®

Related Videos

Rebuilding MV Pumps

Learn how to rebuild your MV (Multi-Viscosity) pumps.

Tips & Tricks of Working with Coaxial Tubing

Learn tips for working with coaxial tubing.

Priming A Pump-Based MQL System

In this how-to video, the procedure for priming a pump-based MQL systems is outlined

Working With The Redesigned Capillary Splicer

Learn how to replace nozzles, shorten or replace co-axial hose or retrofit your system to use the improved capillary splicer design.

Testimonial Video - Sigma Machine

Tia Stevenson from Sigma Machine talks about the Quantum™ and Coolube® lubricants.

MQL Minute #9

In this MQL Minute, John and Larry discuss Unist MQL systems with multiple outputs.

MQL Minute #7

Unist multi-viscosity (MV) pumps are discussed in this MQL Minute.

MQL Minute #6

Learn how to best position your nozzles for milling operations in this MQL Minute.

Setting Up Your Coolubricator System

Learn how to do initial setup on a Coolubricator™ system.

MQL Minute #4

In this MQL Minute, John and Larry discuss the differences between Unist Coolubricator™ and Serv-O-Spray™ systems

What is MQL?

An introduction to Minimum Quantity Lubrication (MQL).

MQL Minute #3

John and Larry take a look at some dry chips in the Unist shop.

MQL Minute #1

This MQL Minute provides a general overview of Unist MQL (Minimum Quantity Lubrication) systems.

Installing Coax Nozzles & Splicer Pins

This video demonstrates how to install co-axial nozzles and splicer pins in a Unist MQL system.